Introduction

From now on, deep cutting is ...

Deeper!! From electrodischarge machining to direct machining

Faster!! To higher-efficient direct machining

Deeper!! From electrodischarge machining to direct machining

Faster!! To higher-efficient direct machining

Features

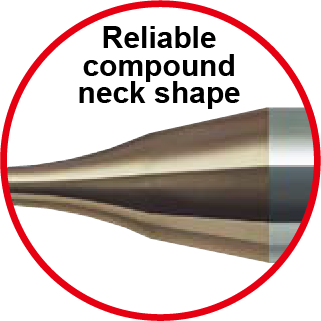

1.Compound neck shape

The compound neck shape with results proven by the Epoch Deep Series is used.

Breakage resistance is improved even for endmills with long below-neck lengths, so that stable deep machining can be performed.

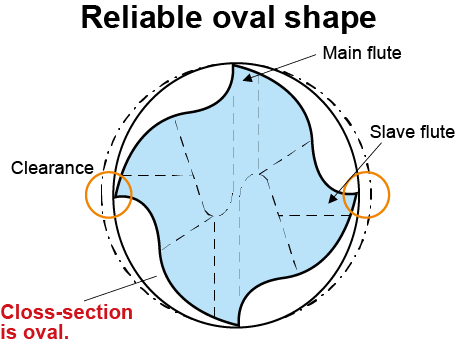

2.Oval effect

The flute cross-section is the oval shape with results proven by Epoch Turbo Mills.

It suppresses vibrations, particularly when machining corner areas, so that stable high-efficient cutting can be performed.

It suppresses vibrations, particularly when machining corner areas, so that stable high-efficient cutting can be performed.

3.High-rigidity flute shape

The corner R flute shape is the same chipping-resistant, high-rigidity flute type that is used the the Epoch Turbo Mills. Machining with high per-flute feed amounts is possible and increases machining efficiency.

4.TH Coating

- A newly developed nanocomposite coating material is able to withstand high cutting temperatures.

Through the use of a new structure made up of nanocrystal material, a higher hardness of coating is achieved. - Enables high-quality machining with long life of hardened steel

(45 to 65HRC), pre-hardened steel, etc.

Catalog Download

PDF files are in Adobe's Portable Document Format. To view them you need Adobe® Reader® by Adobe Systems Incorporated.