Introduction

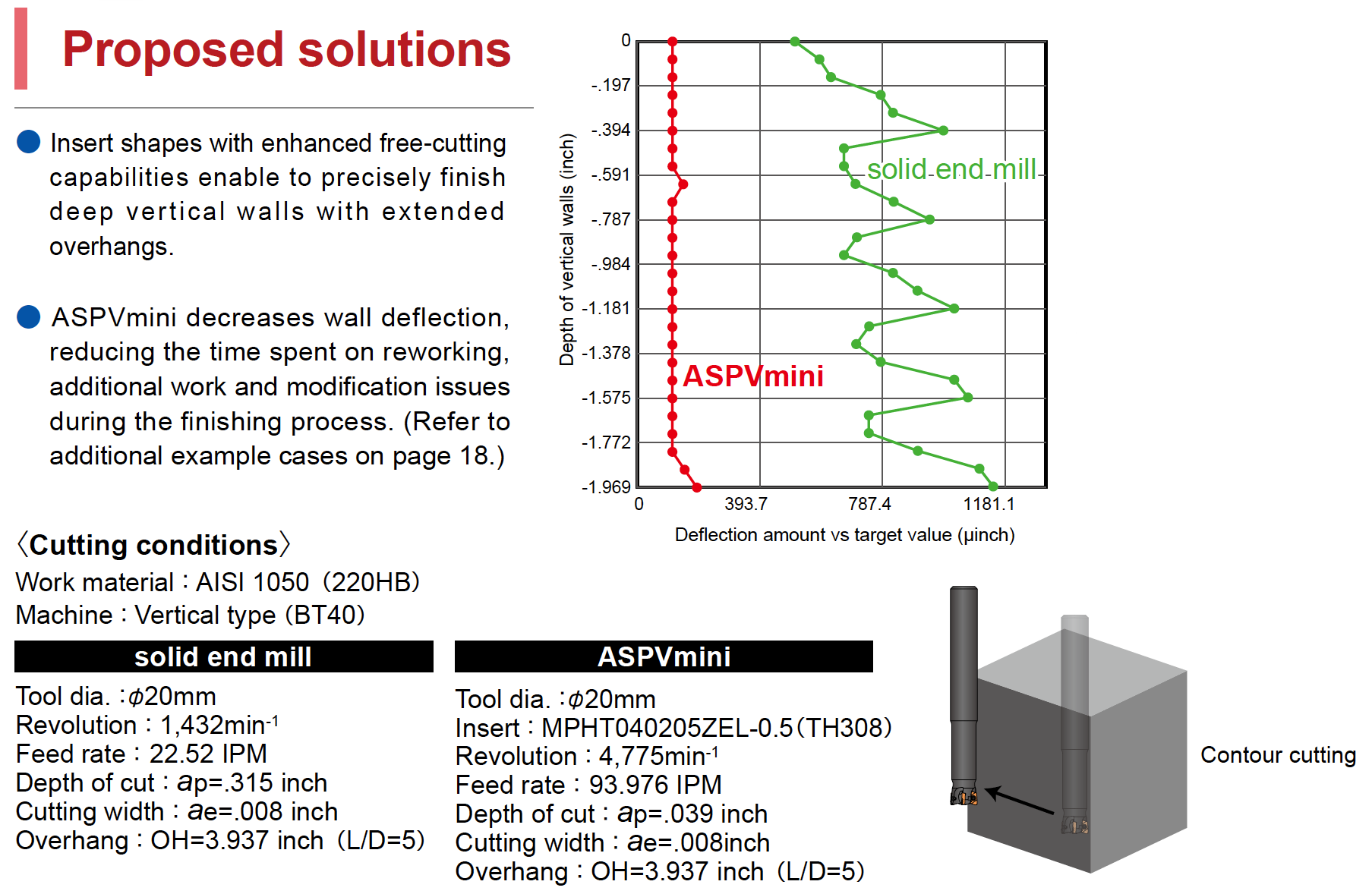

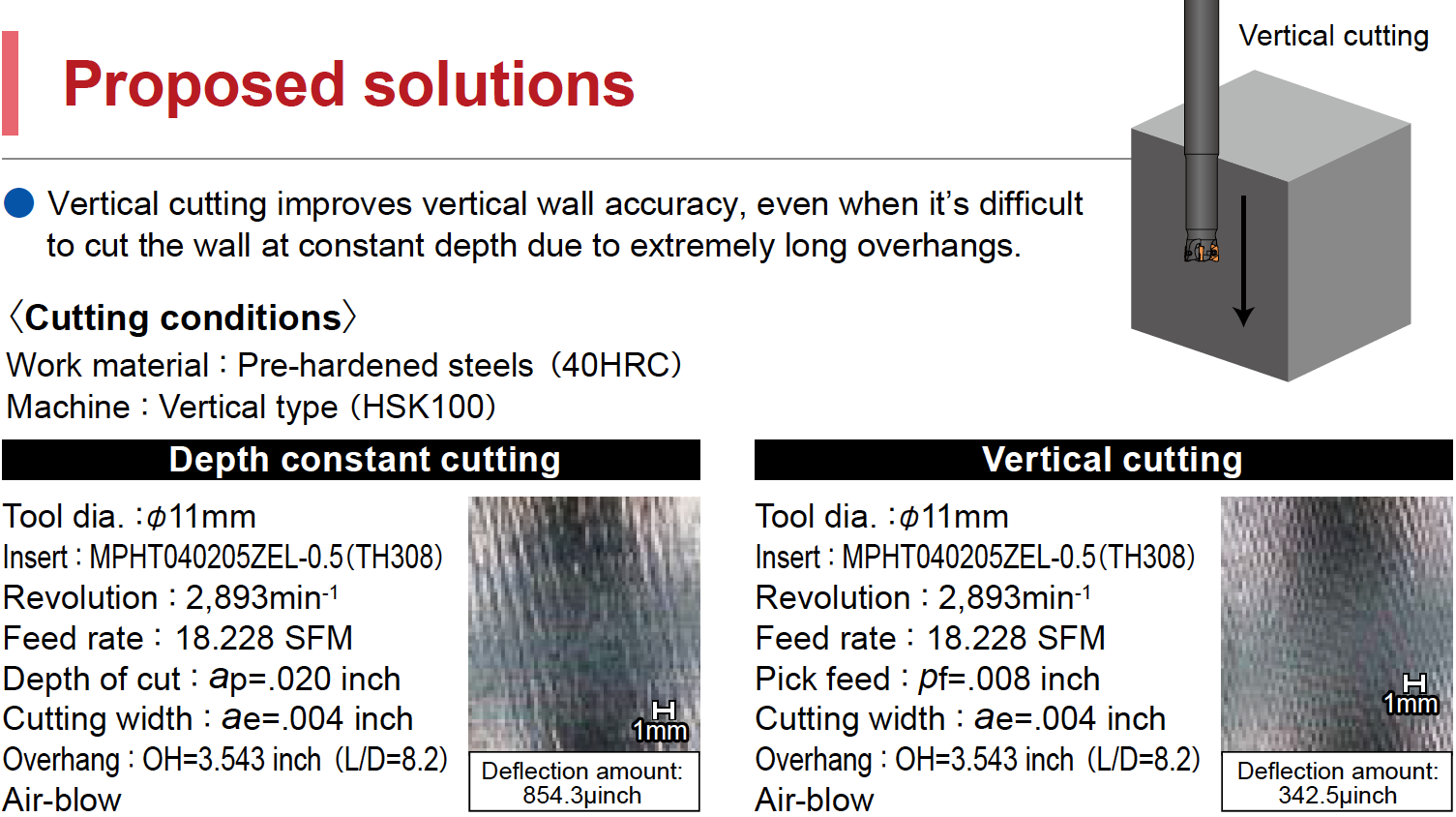

- A high-precision finishing tool has been added to the small-diameter multi-flute series. The free-cutting flute shape solves the problems of vertical wall machining.

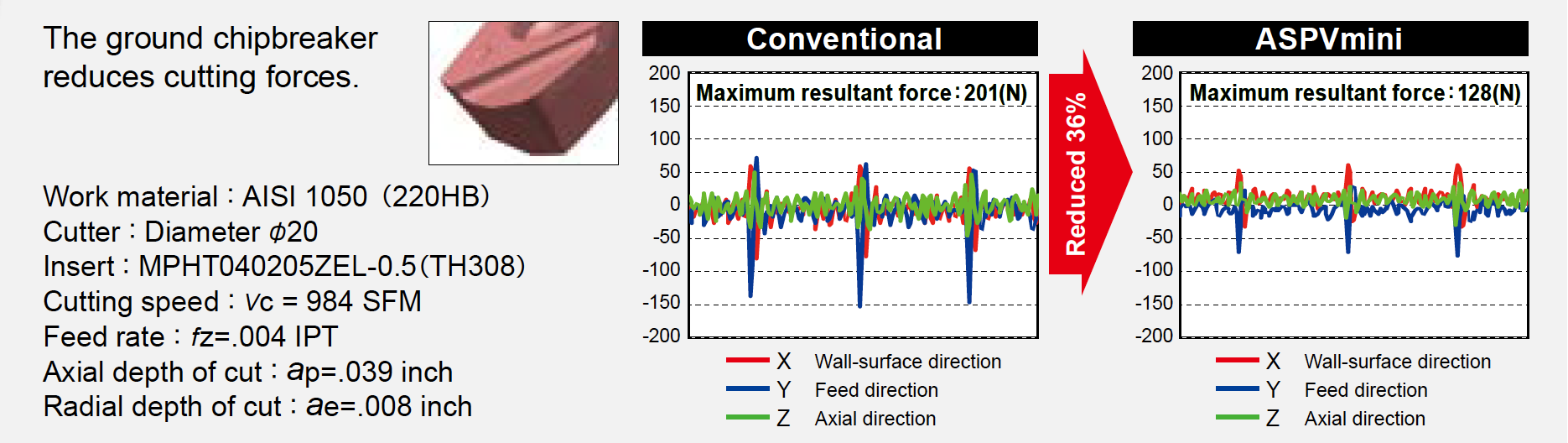

- A sharpened chipbreaker is used to maintain high machining dimensional accuracy even when the tool protrudes for a long time.

- Small-diameter multi-flute specification enables high-efficiency machining and enables replacement from solid

- Lineup of inserts with wiper blades for each R size makes it possible to increase the feed rate when finishing the bottom surface.

- The new grade "TH308" has excellent wear resistance and maintains high surface quality and precision

- The insert has two corners on one side.

Features

1.[Problem] The wall falls down and does not meet the desired dimensional accuracy. It is a waste of time to reprocess and reprocess.

2.[Problem] High verticality is desired even in deep areas with an L/D of 8 or more.

3.[Problem] A tool wears out in a long-time finish machining, and the surface quality and dimensional accuracy are not stable.

Catalog Download

PDF files are in Adobe's Portable Document Format. To view them you need Adobe® Reader® by Adobe Systems Incorporated.