Introduction

- High accuracy is exhibited from the ball tip to the outer circumference – Set up R accuracy: ±0.015mm (Insert R accuracy ±0.01mm or less) –

- Excellent cutting performance and beautiful cutting surface finish.

- High-performance coated inserts provide long life.

Features

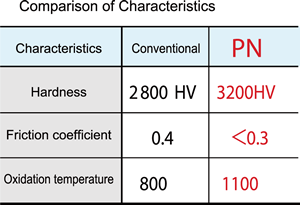

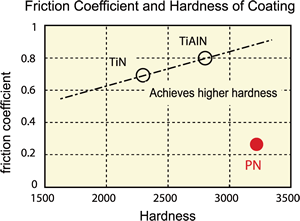

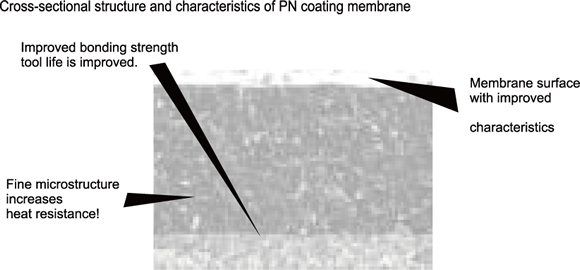

1.New PVD Nano Technology

PN Coating: Industry's first multi-layer structure provides improved adhesion and membrane hardness as well as improving the oxidation-resistance temperature. PN Coating improves the friction coefficient, reduces generation of heat while cutting.

Strengths: Exhibits stable tool life in cutting materials such as plastic injection molds etc. where tool seizure often occurs. Achieves longer tool life in cutting prehardened steel such as carbon steel, alloy steel, stainless steel, hot and cold tool steel, etc. PN08M adopts micro-grain substrate and PN coating.

Strengths: Exhibits stable tool life in cutting materials such as plastic injection molds etc. where tool seizure often occurs. Achieves longer tool life in cutting prehardened steel such as carbon steel, alloy steel, stainless steel, hot and cold tool steel, etc. PN08M adopts micro-grain substrate and PN coating.

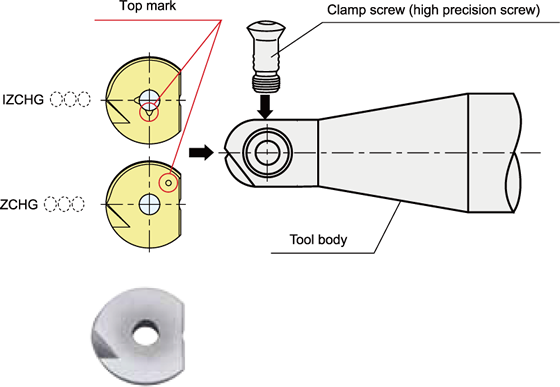

2.Insert Installation

To meet the specification for precision of ±0.015mm, please follow this procedure:

- Clean the inseart seat: Using compressed air or similar, clean the seat.

- Put in the insert with its top mark positioned to the screwtightening side of the tool body.

- Tighten the clamp screw with the special wrench. Please do not press down on the insert during this tightening process.

- This is the end of insert set-up.

Catalog Download

PDF files are in Adobe's Portable Document Format. To view them you need Adobe® Reader® by Adobe Systems Incorporated.