Features

High Feed Radius Mill TD4N type

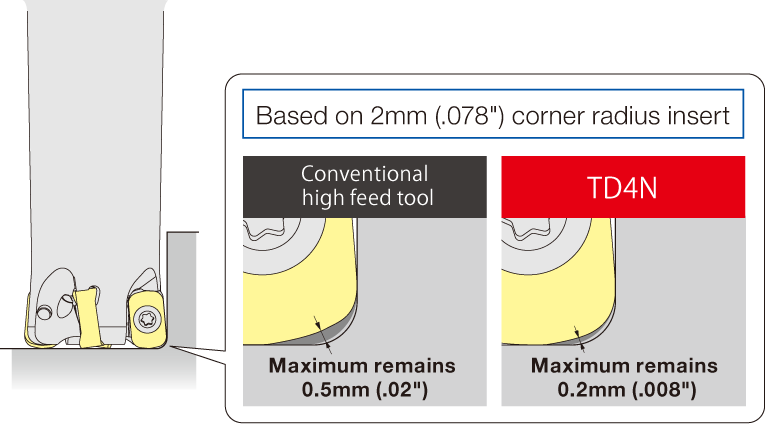

1.Reduces uncut portion on work pieces

The cutting edge geometry of the TD4N is designed to minimize remaining stock in the uncut portion of the insert to reduce process variability and cycle time.

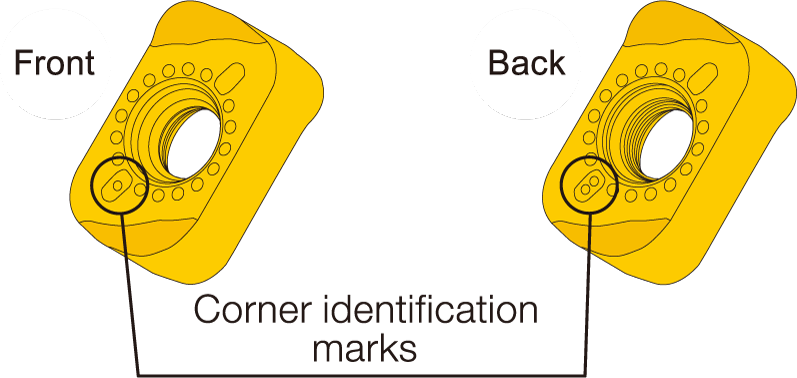

New insert design doubles usable corners from 2 to 4 without impacting edge security or performance.

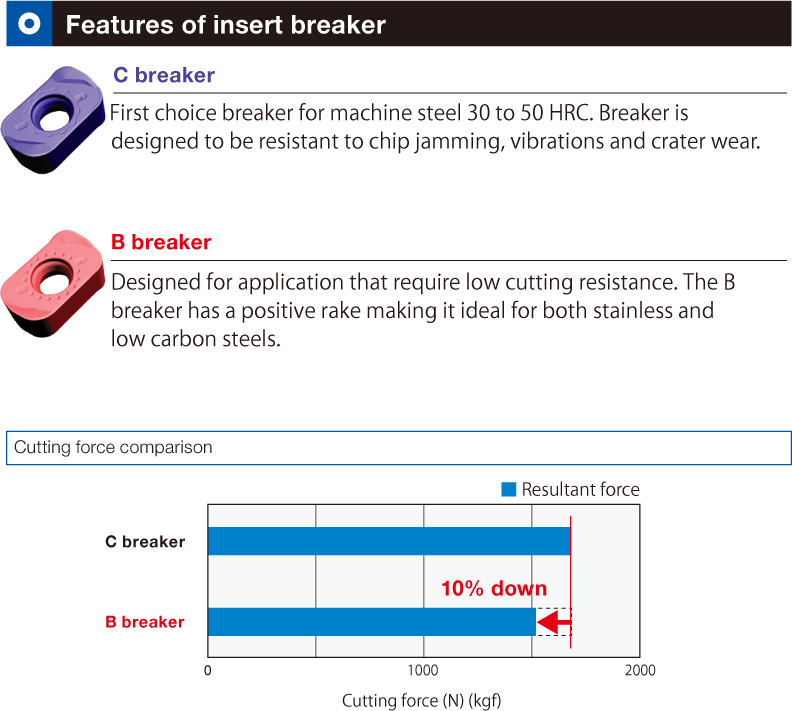

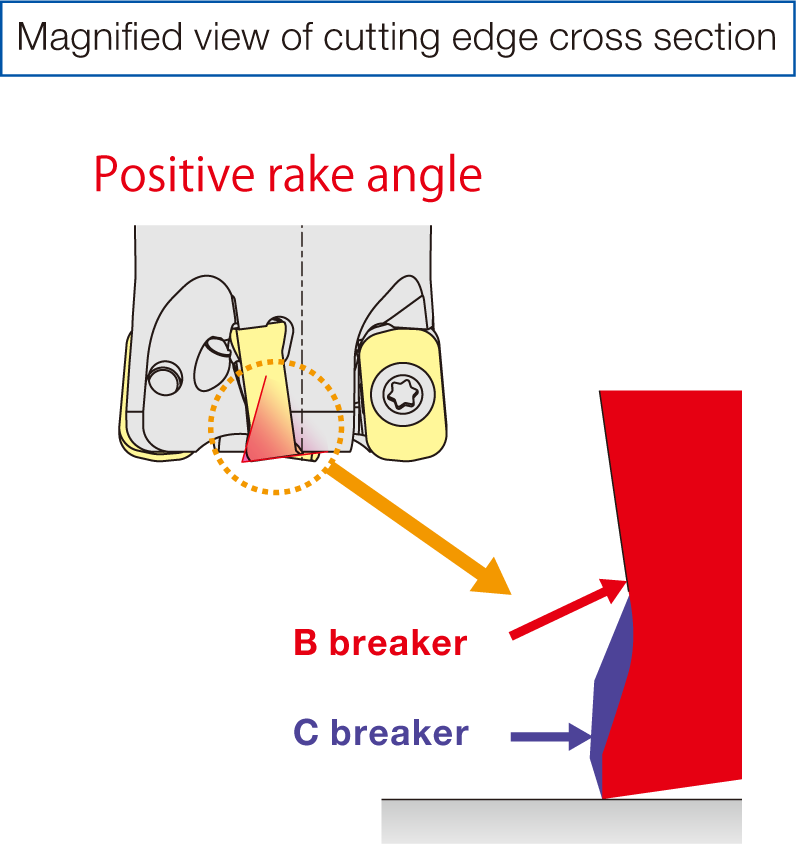

2.Economical 4-corner inserts with chip breakers for various applications

The TD4N is engineered to utilize both sides of the insert doubling cutting edges from 2 to 4 while maintaining performance and edge security of a single sided insert. As an added plus, the chip breaker rake angle was increased to reduce cutting forces and improve chip discharge.

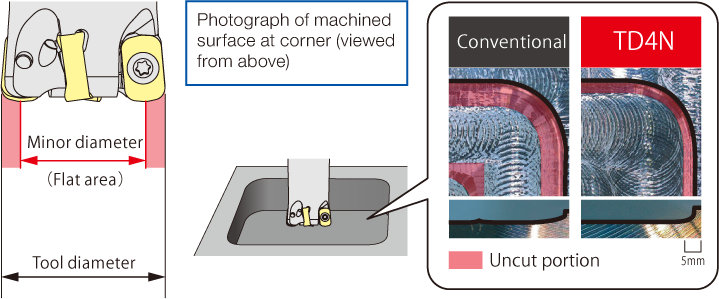

3.Large minor cutting diameter minimized stock variation

Compared to conventional high feed tools, TD4N high feed cutters have a large minor diameter. The large minor diameter minimizes the uncut material in shoulders and enables an increased width of cut -ae- for improved cutter paths and floor blends without sacrificing performance.

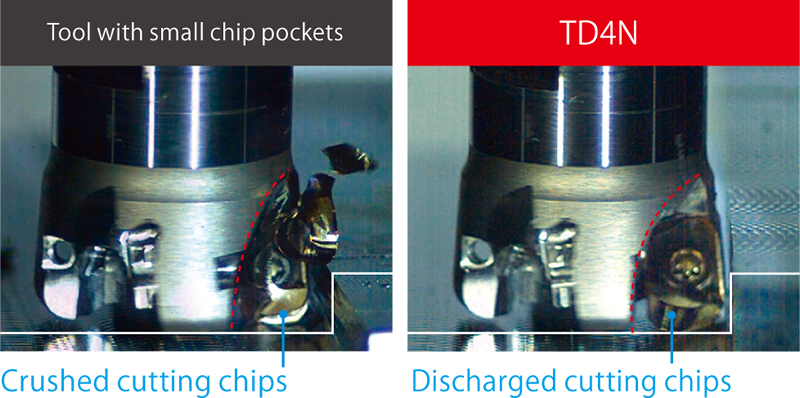

4.Excellent chip discharge characteristics

The TD4N is engineered to curl the chip up and into the chip pocket. This break through concept in high feed milling chip control minimizes the possibility of chip jamming especially when machining shoulders.

Catalog Download

PDF files are in Adobe's Portable Document Format. To view them you need Adobe® Reader® by Adobe Systems Incorporated.